Advantages of Copper End Feed Fittings

Copper end feed fittings offer several advantages over traditional soldered fittings. Firstly, they provide a reliable and durable connection that minimises the risk of leaks. The absence of solder also means there’s no need for an open flame during installation, reducing the risk of fire hazards. Additionally, the capillary action of end feed fittings ensures a tight connection that is resistant to vibration and movement. Copper end feed fittings are also resistant to corrosion, making them suitable for both indoor and outdoor applications.

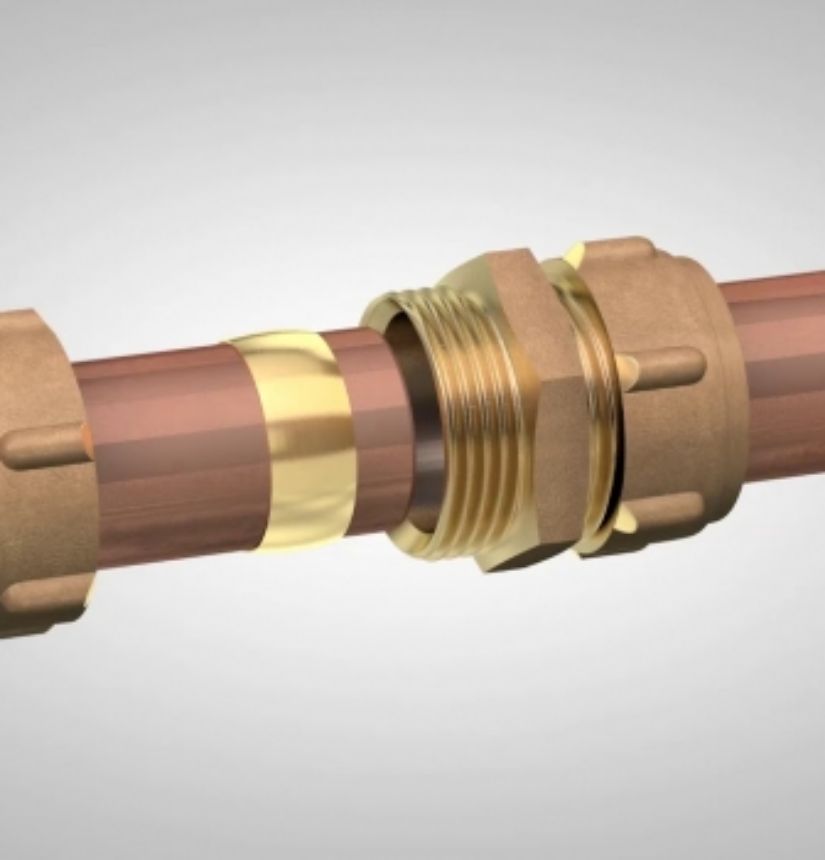

Types of Copper End Feed Fittings

Copper end feed fittings packs come in various types, each serving specific plumbing needs. Here are some common types of fittings you can find in these packs:

- Straight Couplings: Used to join two straight sections of copper pipe.

- Elbows: Used to change the direction of the pipe at a 90-degree angle.

- Tees: Allow for a connection of three pipes at a 90-degree angle, forming a T-shape.

- Reducers: Used to connect pipes of different diameters.

- Caps: Provide a seal for the end of a pipe, preventing the flow of water or gas.

- Adapters: Allow for connections between copper pipes and other pipe materials.

- Stop Ends: Similar to caps, they provide a seal but can be easily removed if needed.

- Couplers: Join two pipes together in a straight line.

- Equal Crosses: Used to create a four-way intersection with equal pipe diameters.

- Unequal Crosses: Similar to equal crosses, but with different pipe diameters.

- End Feed Tap Connectors: Connect copper pipes to taps or faucets.

- End Feed Double Check Valves: Used to prevent backflow in plumbing systems.

- End Feed Gate Valves: Control the flow of water or gas in the plumbing system.

- End Feed Service Valves: Provide an access point for maintenance or repairs.

- End Feed Compression Tees: Combine compression fittings with end feed fittings for versatile connections.

Where To Buy Copper End Feed Fittings?

You can purchase an extensive range of copper fittings in our online store. Use the button below to start ordering.

PressIT UK are industry experts in everything pressing and plumbing in the UK and Ireland. We stock a comprehensive range of copper end fittings packs to help you save on bulk purchases. Save up to 14% off our website prices when you select a copper fittings plan!

Copper end feed fittings packs are comprehensive sets that include a variety of fittings required for plumbing installations. These are designed to provide plumbers with a convenient and cost-effective solution, ensuring they have all the necessary fittings at hand. From straight couplings and elbows to tees and caps, these packs cover a wide range of fitting types, allowing for versatile plumbing applications.

Applications of Copper End Feed Fittings

Copper end feed fittings are versatile and find applications in various plumbing systems, including:

Plumbing Systems: Used in residential, commercial, and industrial plumbing installations for water supply and drainage.

Heating Systems: Essential for connecting radiators, boilers, and underfloor heating systems.

HVAC Systems: Used in heating, ventilation, and air conditioning systems for efficient heat transfer.

Gas Supply Systems: Provide secure connections for natural gas or propane supply lines.

Installation Process of Copper End Feed Fittings

Proper installation is crucial to ensure the effectiveness of copper end feed fittings. Here’s a step-by-step guide to the installation process:

Preparing the Pipes: Cut the copper pipes to the desired length and ensure they are clean and free from debris.

Applying Flux: Apply a thin layer of flux to the outer surface of the pipe and the inner surface of the fitting to promote solder flow.

Assembling the Fittings: Insert the fitting onto the pipe, ensuring it fits snugly and is aligned correctly.

Applying Heat: Use a blowtorch to heat the joint evenly until the solder melts and fills the gap between the pipe and the fitting.

Finalising the Connection: Remove the heat and allow the joint to cool down naturally. Wipe away any excess solder or flux.

Maintenance and Care of Copper End Feed Fittings

To ensure the longevity and optimal performance of copper end feed fittings, regular maintenance is necessary. Here are some maintenance tips:

Inspect the fittings periodically for signs of corrosion or leaks.

Keep the fittings clean and free from debris to maintain proper flow.

Check for any loose fittings and tighten them if necessary.

If repairs or modifications are required, use the proper tools and follow the installation process carefully.

Copper end feed fittings packs are indispensable for reliable and efficient plumbing connections. Their solder-free design, durability, and resistance to corrosion make them a preferred choice for professional plumbers and DIY enthusiasts alike. By understanding the types, installation process, and applications of copper end feed fittings, you can ensure successful plumbing installations and enjoy long-lasting, leak-free connections.

FAQs

- What is the difference between end feed and solder ring fittings? End feed fittings rely on capillary action to draw solder into the joint, while solder ring fittings have pre-applied solder.

- Can copper end feed fittings be used with other pipe materials? Copper end feed fittings are specifically designed for use with copper pipes, but adapters can be used to connect them to other pipe materials.

- Are copper end feed fittings suitable for both hot and cold water systems? Yes, copper end feed fittings are suitable for both hot and cold water systems due to their resistance to high temperatures and corrosion.

- How long do copper end feed fittings last? With proper installation and maintenance, copper end feed fittings can last for several decades.

- Can copper end feed fittings be used for underground applications? Yes, copper end feed fittings can be used for underground applications, provided they are adequately protected from moisture and corrosion.